FA-1210MB/FA-1210MD/FWM-1210MBD

Adjustable Shock Absorber

Bansbachs industrial shock absorbers are a superior alternative to coil springs or rubber bump stops for energy absorption and linear deceleration. We offer many different models from mild to extreme. Our shock absorbers are the perfect solution for a wide range of applications, from a simple cabinet door, to the corrosive environments of the medical field, or the extreme environment of industrial machine equipment. Bansbach shock absorbers are designed to absorb the impact with no bounce back. This steady, gradual deceleration allows faster cycle rates, increased equipment life, and higher production rates while reducing maintenance expenses.

| Model | Stroke mm | Max. absorption energy J (kgfm) | Max. equivalent mass kg (kgf) | Range of impact rate m/s | Orifice type |

|---|---|---|---|---|---|

| FA-1210MB-S/C | 10 | 2.94 (0.3) | 30 (30) | 0.3 ~ 1 | Single-orifice |

| FA-1210MD-S/C | 4.9 (0.5) | 4 (4) | 0.7 ~ 3 | Multiple-orifice | |

| FWM-1210MBD-S/C | 30 (30) | 0.3 ~ 2 | Multiple-varying orifice |

| Max. drag N (kgf) | 1470 (150) |

|---|---|

| Max. cycle rate cycle/min | 60 |

| Max. absorption energy per minute J/min (kgfm/min) | 98 (10) |

| Recovering power of the piston rod N (kgf) | 9.8 (1.0) or lower |

| Operating temperature °C | -5 ~ 70 |

| Mass: S type g | 44 |

| Mass: C type g | 47 |

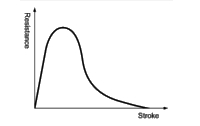

| Model | Orifice type | Application | Absorption |

|---|---|---|---|

| FA-1210MB series | Single orifice | For low speed |  |

| FWM-1210MBD series | Multiple-varying orifice | For medium speed |  |

| FA-1210MD series | Multiple-orifice | For high-speed |  |

| Eccentric angle adaptor OP-010KB | Stopper nut OP-020KB | Liquid-proof cap |

|---|---|---|

|  |  |

| Square flange OP-040KB | Holder with a switch OP-030KB-2 | |

|  | |

|

* Do not use this product without carefully reading the attached owner's manual. * Ensure that an external stopper (Stopper nut OP-020KB) is also used. * Do not turn the oil inlet screw located at the bottom of the main unit. * Ensure that sufficient mounting strength is secured for this product. (As a guideline, it should be 2 to 3 times the maximum drag listed in the catalogue.) * Do not use this product in a vacuum or a location where it may come in contact with oil. * Ensure that an eccentric load is not applied to the soft absorber. (Allowable eccentric angle: within ±2.5°) |