Information & Precautions

Shock Absorbers

Basic Structure and Principles: Shock Absorber

| Shock absorbers have two types of structure: an adjustable type in which the absorption characteristics can be adjusted, and a fixed type, which is non-adjustable. Each structure is shown below. |

| Adjustable Type |

By rotating the adjustment knob (adjustment shaft) located towards the rear of the main body, the amount of oil flowing out of the pressure chamber can be adjusted, which in turn adjusts the absorption characteristics. For the multiple types, the adjustment can only be made with the final orifice; therefore, the range of adjustment is limited. The adjustment range is wider in the single types. Because the orifice area changes in an analog manner, fine-tuning of the absorption characteristics is possible. By rotating the adjustment knob (adjustment shaft) located towards the rear of the main body, the amount of oil flowing out of the pressure chamber can be adjusted, which in turn adjusts the absorption characteristics. For the multiple types, the adjustment can only be made with the final orifice; therefore, the range of adjustment is limited. The adjustment range is wider in the single types. Because the orifice area changes in an analog manner, fine-tuning of the absorption characteristics is possible. |

| Fixed Type |

Because it has no adjustment mechanism, the overall length is shorter than the adjustable type. By customizing your orifice design, optimal absorption characteristics can be obtained. In addition, because the characteristics are fairly uniform, more than two of them can be used in parallel. For the fixed type FK series, high-speed, mid-speed, and low-speed types are generally available to accommodate various speeds. Because it has no adjustment mechanism, the overall length is shorter than the adjustable type. By customizing your orifice design, optimal absorption characteristics can be obtained. In addition, because the characteristics are fairly uniform, more than two of them can be used in parallel. For the fixed type FK series, high-speed, mid-speed, and low-speed types are generally available to accommodate various speeds. |

| Principles of Energy Absorption |

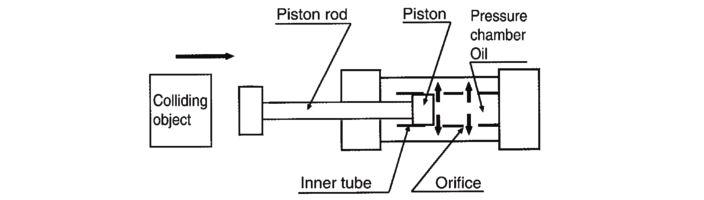

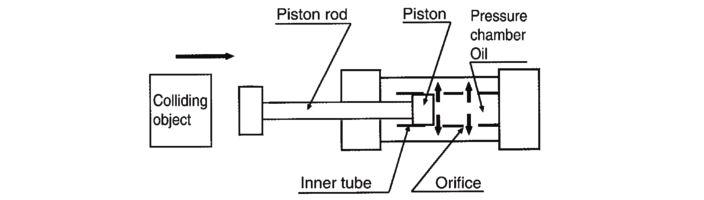

As shown below, when an object hits the piston rod, the motion is transferred to the oil in the pressure chamber through the piston rod. As a result, the oil inside the pressure chamber flows out of the orifices located in the inner tube. This causes compression in the pressure chamber. The product of this hydraulic pressure and the pressure applied area of the piston is resistance, which acts on the colliding object. shock absorbers use this resistance to apply the brake to the colliding object, slowing it down. The hydraulic pressure generated inside the pressure chamber is proportional to the square velocity of the colliding object, as long as the orifice size, oil viscosity, etc. are constant. This is called velocity-squared resistance.

|

What is a Shock Absorber?

| In order to increase the productivity of industrial machines, such as automatic assembling machines, various transportation machines, machines tools, and so on, their operating parts have been made to work faster. However, the resulting impact, vibration, and noise have caused adverse effects on the machine's performance and on the working environment. A shock absorber is an extremely convenient hydraulic buffer that can solve such problems. There are similar devices made of rubber, springs, or devices that use pneumatic pressure, but none of them rival the impact absorption characteristics of the hydraulic type. |

Purpose of the Accumulator

| As shown below, when work collides with a shock absorber, the piston rod initiates a stroke, causing the oil to flow into the other side of the piston through the orifices. In short, the capacity of oil chamber B is reduced by the piston rod, and not all of the oil in oil chamber A is able to flow into the oil chamber B. In order to secure the capacity reduced by the piston rod, a self-foaming nitrile rubber is provided. The pressure of the oil compresses the rubber so that it absorbs the capacity that is equivalent to the piston rod. This is the role of an accumulator. Although silicone oil is used in a shock absorber, there are certain types of hydraulic oils that do not work well with certain types of accumulator. Using improper hydraulic oil causes the nitrile rubber to harden, reducing the durability of the shock absorber. |

Warning!

| *Do not throw into a fire |

| As the products contain oil, throwing them into a fire may cause them to ignite, resulting in injuries. |

Caution!

| *Do not operate without sufficient mounting strength |

| Operating with insufficient mounting strength may damage the main machine and cause injuries.Ensure sufficient mounting strength of maximum drag x safety factor (Regarding maximum drag, please refer to the catalogue or contact our sales department.) |

| *Do not operate without an external stopper |

| Without an external stopper, the main machine may become damaged due to bottoming. Ensure that an external stopper is set in the prescribed location for each type before operating the product. (For the locations of external stoppers, please refer to the catalogue or to the owner's manual.) |

| *Do not attach using incorrect tightening torque |

| Using an incorrect tightening torque when attaching may cause operational failure and damage to the main machine. |

| *Dislodged retaining ring |

| Failure to adhere to the specifications listed in the catalogue may cause the internal pressure of the inner tube to raise to a dangerous level where the retaining ring may become dislodged and interior parts may shoot out, causing injuries. Do not bring your face close to a shock absorber that has a retaining ring while it is operating. |

| *Do not discard oil more than is necesssary |

Discarding the oil contained in dampers more than is necessary will pollute the environment.

Dispose the oil according to laws concerning waste management and cleaning. |

| Scattering pieces due to cap damage |

| Failure to adhere to the specifications listed in the catalogue may cause the cap to break, resulting in scattering pieces that may cause injuries.Please install an anti-scattering cover. |

| Eccentric load and eccentric angle |

| When a load collides at an eccentric angle of ±2.5° or larger, recovery failure due to a bent piston rod and performance degradation due to eccentric friction on the sliding part may occur, causing damage to the main machine. |

| Operating temperature |

| When using a shock absorber, ensure that it is used within the operating temperature. Failure to do so will have adverse effects on the packing and accumulator that will reduce the product life, which may damage the main machine. (For the appropriate operating temperature, please refer to the catalogue or to the owner's manual.) |

| Usage environment |

| This product cannot be used in a vacuum or under high pressure, as this will cause damage to the main machine.Do not use in an environment where chips, cutting oil, water, etc. can come in contact with the piston rod. This will damage the packing, resulting in oil leakage, which leads to operational failure and damage to the main machine. |

Bansbach Easylift of North America is not responsible for any secondary accidents caused by a shock absorber. The following are two examples of such secondary accidents caused by a shock absorber:

(Example 1) An overload causes the piston rod to break, resulting in a facial injury. Countermeasure – install a cover.

(Example 2) The drag causes the cap to break. The cap then gets lodged inside the machine, damaging it.

Countermeasure – install a tray, etc. under the shock absorber. The user should implement preventative measures against such secondary accidents. |

By rotating the adjustment knob (adjustment shaft) located towards the rear of the main body, the amount of oil flowing out of the pressure chamber can be adjusted, which in turn adjusts the absorption characteristics. For the multiple types, the adjustment can only be made with the final orifice; therefore, the range of adjustment is limited. The adjustment range is wider in the single types. Because the orifice area changes in an analog manner, fine-tuning of the absorption characteristics is possible.

By rotating the adjustment knob (adjustment shaft) located towards the rear of the main body, the amount of oil flowing out of the pressure chamber can be adjusted, which in turn adjusts the absorption characteristics. For the multiple types, the adjustment can only be made with the final orifice; therefore, the range of adjustment is limited. The adjustment range is wider in the single types. Because the orifice area changes in an analog manner, fine-tuning of the absorption characteristics is possible.  Because it has no adjustment mechanism, the overall length is shorter than the adjustable type. By customizing your orifice design, optimal absorption characteristics can be obtained. In addition, because the characteristics are fairly uniform, more than two of them can be used in parallel. For the fixed type FK series, high-speed, mid-speed, and low-speed types are generally available to accommodate various speeds.

Because it has no adjustment mechanism, the overall length is shorter than the adjustable type. By customizing your orifice design, optimal absorption characteristics can be obtained. In addition, because the characteristics are fairly uniform, more than two of them can be used in parallel. For the fixed type FK series, high-speed, mid-speed, and low-speed types are generally available to accommodate various speeds.